TAPERED ROLLER BEARINGS

Taper roller bearings have tapered inner and outer ring raceways between which tapered rollers are arranged. If extended, the tapered surfaces converge towards a single point on the bearing axis. This means that rolling conditions are at an optimum. Their design makes taper roller bearings particularly suitable for the accommodation of combined (radial and axial) loads. The axial load carrying capacity of the bearings is largely determined by the contact angle a, which corresponds to the angle of the outer ring raceway. The larger this angle, the larger the axial load carrying capacity. Taper roller bearings are generally of separable design, i.e. the inner ring with roller and cage assembly forms a unit, which can be mounted separately from the outer ring.

Galaxy Bearing Ltd. manufactures single row & double rows taper roller bearings with metric as well as inch dimensions. The single row bearings listed in the following tables are the most prominent. Double row taper roller bearings are included in this catalogue.

As a result of the continuous improvements made to Galaxy Bearing Ltd. taper roller bearings, which represents the latest state of the art. Raceway has also been markedly improved by the "logarithmic" profile, which provides for optimum stress distribution in the bearing avoiding edge loading. Optimized raceway surfaces promote lubricant film formation and correct motion of the rollers. These improvements have considerably enhanced the performance of taper roller bearings. The advantages of the new bearings compared with conventional designs include.

- Greatly reduced friction,

- Increased load carrying ability,

- More reliable bearing adjustment, and

Marked increases in operational reliability even during the first hours of service, and under heavy loads and misaligned conditions.

- Single Row Tapper Roller Bearings

Single row taper roller bearings are able to accommodate axial loads acting in one direction only. Under radial loads, an axial force is produced in the bearing, which must be counteracted. Therefore, it is customary for the single row taper roller bearings to be adjusted against a second taper roller bearing.

Galaxy Bearing Ltd. produces a large number of sizes of single row taper roller bearings including both metric and inch.

This range covers bearings having very low cross section, which enable very compact bearing arrangements to be designed, as well as bearings having a large contact angle intended for heavy axial loads. - Bearing Designations

Metric bearings

The designation of Bearings is as per the international standard, ISO 355-1977. Metric bearings identified by the prefix K-J follow the designation system described below for inch-size bearing.

Inch sizes

Inch-size taper roller bearings are designated following a system which is completely different from that used for metric taper roller bearings. The inner ring with roller and cage assembly, known as the cone, and the outer ring (cup) have individual designations. The complete bearing designation consists of the cone designation followed by the cup designation, the two designations being separated by an oblique stroke. The cones and cups belong to various “bearing series” Any cup belonging to a particular series can be assembled with any cone of the same series to form a complete bearing.

The cone, cup and bearing series designation generally consist of a three to six-figure combination and may be preceded by a letter combination (LL, L, LM, M, HM, H and HH). The letters serve to indicate whether the bearing series is light or heavy.

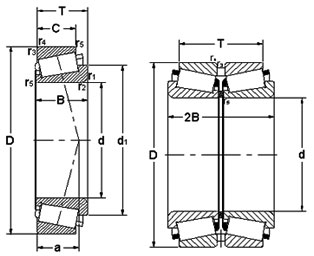

- Dimensions

Metric bearings

The boundary dimensions of the metric taper roller bearings listed in the tables confirm to ISO 355-1977 except for those bearings carrying designations prefixed by K-J.

Inch sizes

The boundary dimensions of the inch-size taper roller bearings listed in the tables. Generally speaking, inch-size bearings should only be used in new designs for which no suitable metric bearing can be found.

- Misalignment

The ability of single row taper roller bearings to accommodate angular misalignments of the inner ring with respect to the outer rings is limited to a few minutes of arc so that they are only able to compensate for alignment errors of this magnitude. For Galaxy Bearing Ltd. bearings which have the logarithmic profile. This guideline value applies provided the positions of the shaft and housing axes are constant. Larger misalignments are possible, depending on the load and requisite life. In such cases it is recommended that the Galaxy Bearing Ltd. application service be contacted.

- Tolerance

The inner rings with roller and cage assembly and outer rings of taper roller bearings having the same designation are interchangeable. The tolerance for the total width (abutment width) T of the bearing will not be exceeded if the cones and cups are interchanged.

- Metric Bearings

Galaxy Bearing Ltd. single row metric taper roller bearings are manufactured to normal tolerances standard & any special class standard as per the customer requirement. Galaxy Bearing Ltd. is also available with a reduced width tolerance class CLN specification. Bearings with designation prefix K-J are manufactured to CLN class tolerances as standard. The values for the normal tolerances as well as those of tolerance classes CLN are given in the tables in the general information of Bearings. The tolerances for the chamfer dimensions are in accordance with ISO 582-1979, in the tables in the general information of Bearings, except for the bearings identified by the prefix K-J which have chamfer dimensions tolerances corresponding to those for inch-size bearings.

- Internal clearance

The internal clearance of Single row taper roller bearings can only be obtained after mounting and is determined by adjustment of the bearing against a second bearing, which provides location in the opposite direction.

- Cages

GBL taper roller bearings have pressed steel cage as standard. Cage are manufacture from CRCA low carbon steel material. For special applications bearings can be supplied with molded polyamide 6.6 cage material.

- Minimum load

In order to guarantee the satisfactory operation of all and roller bearing they must always be subjected to a given minimum radial load. This is also true of taper roller bearings, particular if they run at high speeds where the inertia forces of the rollers and cage, and the friction in the lubricant can have a detrimental influence on the rolling conditions in the bearing and may cause damaging sliding movements to occur between the rollers and raceways. The requisite minimum radial load to be applied in such cases can be estimated from

Frm = 0.02 C

Where

Frm = minimum radial load, N

C = basic dynamic load rating, N - Product Range

Click here to see the complete details in a tabular format.